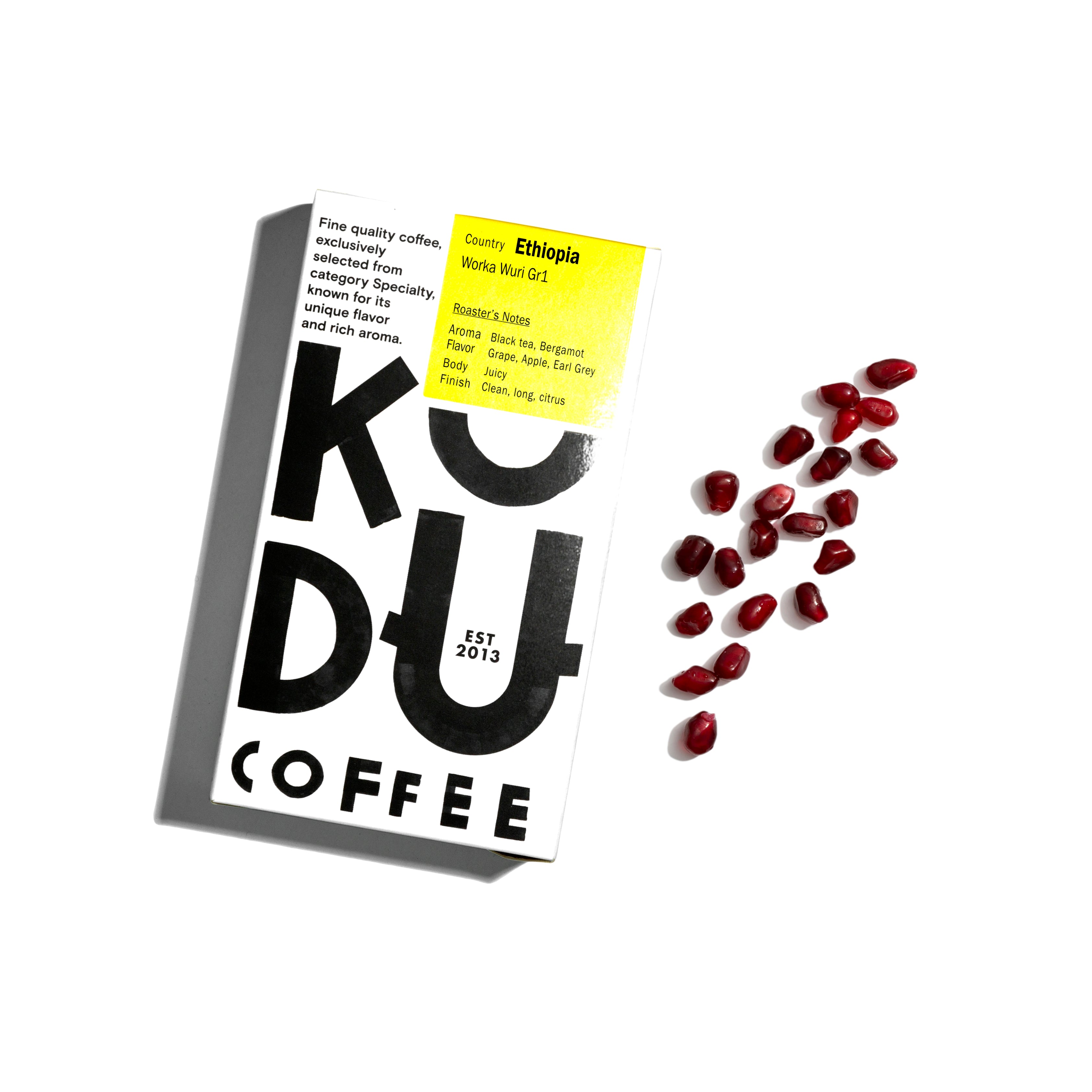

Ethiopia Worka Wuri Gr1 (250g)

A refined and luminous cup featuring elegant black tea and bergamot aromas. The palate shines with crisp notes of grape and red apple, accented by a whisper of Earl Grey tea. The body is silky and velvety, leading to a clean, long-lasting finish with a refreshing citrus lift—an ideal example of Yirgacheffe’s sophisticated character.

FARM: Worka Wuri

The washed method emphasizes clarity, enhancing Worka Wuri’s signature tea-like elegance while supporting consistent and sustainable yields across farming families.

Ethiopia Worka Wuri Gr1 arrived to our roastery via EL CAFÉ, a company established in 2000 by Vasileios G. Anastasopoulos that is solely concerned in the coffee producing countries with discovering new coffee varieties on special farms.

Since then they supplie most of the largest coffee producing companies in Greece, by remaining as a dedicated green coffee import and trading company.

About Worka Wuri Gr1

PRODUCER:400 smallholder farmers

TERROIR:Gedeo Zone

ALTITUDE:2.100 m

PROCESS:Classic Washed

ARRIVED IN:60 kg bags

VARIETIES:Mixed Heirloom

AROMA:Black tea, Bergamot

FLAVOR:Grape, Apple, Earl Grey

BODY:Silky

FINISH:Clean, long, citrus

This lot includes diverse heirloom varieties—native landraces that have evolved over centuries. This genetic diversity contributes to the complexity and layered nuance of the cup, blending floral, fruity, and herbal characteristics in each sip.

Processing Steps

1.Sorting & Depulping: Cherries are sorted by density and then gently pulped.

2.Fermentation: Beans are fermented in clean, shaded tanks for 24–36 hours, keeping fermentation temperatures low to preserve florals and acidity.

3.Washing: Multiple rinses with fresh spring water remove all mucilage.

4.Drying on Raised Beds: Beans are sun-dried on African raised beds for 10–14 days. They are spread thin, covered from direct sun midday, and turned regularly to ensure even drying and avoid over-fermentation.

5.Mill Specifications: The Worka Wuri mill is solar-powered and equipped with aerodynamic fans for ventilation, automated moisture and temperature meters, and stainless steel tanks for fermentation—an investment in precision and bean integrity.

6.Storage & Conditioning: After drying to 11% moisture, beans are moved into GrainPro or jute-lined silos for 15 days of stabilization prior to export, ensuring balance and preservation.